Operating under a comprehensive quality assurance program (ISO 9001:2015 Certified), MCC's non-ferrous capabilities feature:

- Single alloys to bi-metals

- Ability to produce blanks ranging from 7” to 99” in diameter cast to specified shaft sizes

- Standard shape to unique near-net-shape casting processes

- In-house modern CNC turning and milling machining centers

- State-of-the-art melting capabilities

- In-house materials lab for R&D on materials, micro-structure and hardness

- Prompt delivery and superior quality

The advantages of centrifugal casting over static casting are exemplified by test results that show:

- Ultimate tensile strength (UTS) of test bars cut from centrifugal casting is higher in all directions than bars cut from static casting, while yield strength is identical

- UTS is 30% higher in the transverse direction & 36% higher in the longitudinal direction

- Elongation is 50% higher

Our variety of centrifugally cast and machined non-ferrous materials includes:(Click Title to Download PDF)

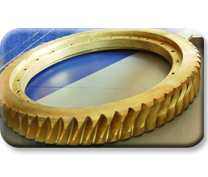

These castings are used in applications ranging from power generation to material handling to elevators. Typical products include:

- Bi-Metallic Gears

- Worm Gear Blanks

- Bushings

- Bearings

- Nuts

- Valve Bodies