|

Excellence in |

|

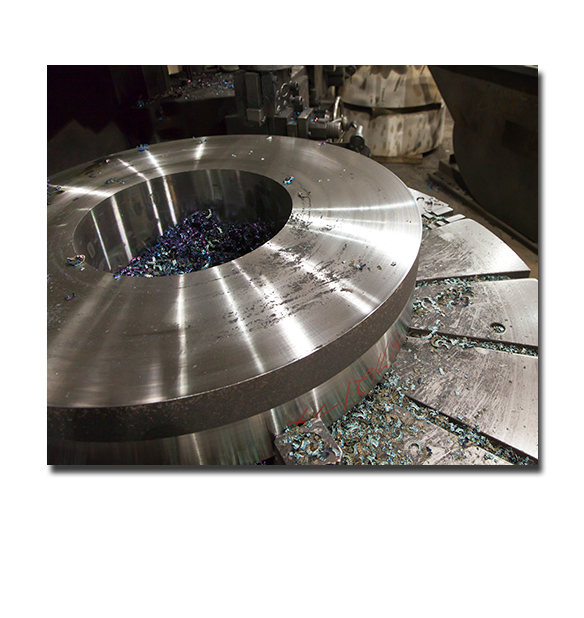

The MCC International centrifugal casting process provides a lower cost method for producing high quality products.

Our unique pressure casting process consists of forcing molten metal against the mold wall under relatively high pressure and rapidly cooling the mold. This combination improves the density of the metal, increases the actual mechanical properties of the casting by 10% to 15% and provides a uniform metallurgical structure.

When parts or components need to meet exacting specifications and tight delivery schedules, MCC has the engineering expertise and manufacturing skills to meet your needs.

Find out why you should make MCC International your single source for centrifugally cast ferrous and non-ferrous products.

- Minimization of Defects

(Shrinkage, Voids, Gas Entrapment)

- Superior (Finer) Grain Structure

- Higher Mechanical Properties (Strength, Ductility, Toughness)

- Directional Solidification that Minimizes Impurities

Our unique centrifugal casting process is a cost-effective way to manufacture an extensive array of quality ferrous and non-ferrous products, including:

- Bearing Parts

- Bi-Metallic Rings

- Bushings

- Gear Blanks

- Nuts

- Rolling Mill Sleeves

- Valve Bodies

M