|

Excellence in |

|

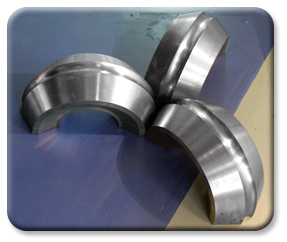

Our centrifugal casting process allows us to cost-effectively manufacture mill rolls and sleeves, and much more. We have the ability to cast and machine complex sleeves ranging from diameters of 8” (50 lbs.) to 60” (22,000 lbs.)

Our unique pressure casting process consists of forcing molten metal against the mold wall under relatively high pressure and rapidly cooling the mold. This production method enables us to produce bi-metallic sleeves that feature high-wear resistant shells with inner cores that are tough and forgiving.

Our superior centrifugally cast sleeves feature micro-structures that offer long life and additional tons rolled per dressing.

With the most modern CNC turning and milling machines, melting capabilities and in-house materials lab, we’re able to manufacture products that meet the most demanding specifications, and deliver them on-time.

In addition, we can take your drawings to create quality products, or we can design ones that meets your particular needs.

M